magnetic components

magnetic components

FERRITE GAPPING

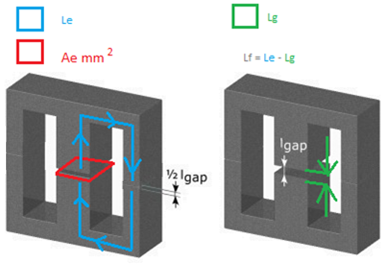

Ferrite gapping involves creating a small air gap in a ferrite core to adjust its magnetic properties.

This is often done to achieve a specific inductance value or to fine-tune the performance of the core in a given application.

The process can be done either by physically grinding the core to the desired dimension or by specifying the required inductance value and tolerance.

This is often done to achieve a specific inductance value or to fine-tune the performance of the core in a given application.

The process can be done either by physically grinding the core to the desired dimension or by specifying the required inductance value and tolerance.

Creating an air gap can reduce Br to increase the magnetic flux density change value Delta/B. After then, the excitation current increases, but the magnetic core volume can be reduced. For magnetic flux work in two-way: Delta/B=2Bm.

In this case, it is also necessary to pay attention to the fact that the volt-second area of the positive and negative changes of the excitation is not equal due to various reasons, and the DC bias problem occurs.

Therefore, a small air gap can be added to the magnetic core, or a DC blocking capacitor can be added in the circuit design.

In this case, it is also necessary to pay attention to the fact that the volt-second area of the positive and negative changes of the excitation is not equal due to various reasons, and the DC bias problem occurs.

Therefore, a small air gap can be added to the magnetic core, or a DC blocking capacitor can be added in the circuit design.

Technisch Adviesbureau Soetens

Best

info @ tas.industries

Brainport Eindhoven

Best

info @ tas.industries

Brainport Eindhoven

High frequency transformer

CMC DMC and filter inductors.

Power Factor correction.

High-frequency inductors

low-frequency power line inductors

specially designed inductors for decoupling and filter applications.

Ferrite / Nanocrystalline / Powder Material

Application onboard charger for electric Vehicels, line and noise filter exc.

CMC DMC and filter inductors.

Power Factor correction.

High-frequency inductors

low-frequency power line inductors

specially designed inductors for decoupling and filter applications.

Ferrite / Nanocrystalline / Powder Material

Application onboard charger for electric Vehicels, line and noise filter exc.

Technisch Adviesbureau Soetens

Best

info @ tas.industries

Brainport Eindhoven

Best

info @ tas.industries

Brainport Eindhoven