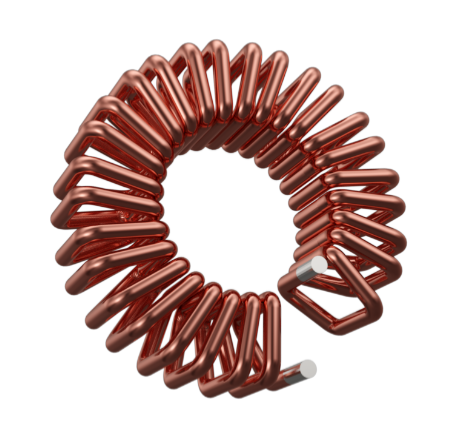

magnetic components

CALCULATORS >> TOROID - EQ - BLOCK - EE - PHYSICS - HFTRANSFORMER - FERRITEGAP

THE CORE

Selecting the optimal core material for transformer design is a critical step that significantly impacts the transformer's performance. Let's take a closer look at the materials of the core :

Core Material Importance:

Selecting the optimal core material for transformer design is a critical step that significantly impacts the transformer's performance. Let's take a closer look at the materials of the core :

Core Material Importance:

- The core material serves as the pathway for magnetic flux, enabling efficient energy transfer between the primary and secondary windings.

- A well-chosen core material is crucial.

- High Magnetic Permeability, allows for effective flux coupling.

- Low Core Losses, minimizes energy dissipation.

- Minimal Hysteresis and Eddy Current Losses , reduces energy wastage.

Isolation transformers are commonly used in various applications:

Sensitive Equipment: Power supplies for computers, medical devices, and laboratory instruments.

Electronics Testing: To isolate test equipment from the power source.

IEC Standarts:

IEC 60664-1

IEC 61558-1

IEC 60335-1

IEC 62368-1.

Sensitive Equipment: Power supplies for computers, medical devices, and laboratory instruments.

Electronics Testing: To isolate test equipment from the power source.

IEC Standarts:

IEC 60664-1

IEC 61558-1

IEC 60335-1

IEC 62368-1.

Selecting the optimal core material for transformer design is a critical step that significantly impacts the transformer's performance. Let's delve into the key considerations and material options:

Core Material Importance:

The core material serves as the pathway for magnetic flux, enabling efficient energy transfer between the primary and secondary windings.

A well-chosen core material exhibits the following characteristics:

High Magnetic Permeability: Allows for effective flux coupling.

Low Core Losses: Minimizes energy dissipation.

Minimal Hysteresis and Eddy Current Losses: Reduces energy wastage.

Core Material Importance:

The core material serves as the pathway for magnetic flux, enabling efficient energy transfer between the primary and secondary windings.

A well-chosen core material exhibits the following characteristics:

High Magnetic Permeability: Allows for effective flux coupling.

Low Core Losses: Minimizes energy dissipation.

Minimal Hysteresis and Eddy Current Losses: Reduces energy wastage.

Temperature Rise Consideration:

- Designers may not always freely choose the switching frequency due to other component constraints.

- As frequency increases, adjust flux density to limit core temperature rise.

- Curves help select flux density while maintaining acceptable core loss levels.

- Remember that the right core material depends on the specific application, operating conditions and desired performance.

- Engineers must carefully evaluate these factors to make informed decisions during transformer design.

IEC Standarts

IEC 60664-1

IEC 61558-1

IEC 60335-1

IEC 61558-1

IEC 60335-1

IEC 62368-1

Isolation

Galvanic Isolation, Isolation Transformers provide galvanic isolation meaning there is no conductive path between the primary (input) and secondary (output) windings. This isolation serves several purposes,

It protects against electric shock by preventing direct contact between energized conductors and earth ground.

Applications

Isolation transformers are commonly used in various applications.

Sensitive Equipment, Power supplies for computers, medical devices and laboratory instruments.

Galvanic Isolation, Isolation Transformers provide galvanic isolation meaning there is no conductive path between the primary (input) and secondary (output) windings. This isolation serves several purposes,

It protects against electric shock by preventing direct contact between energized conductors and earth ground.

Applications

Isolation transformers are commonly used in various applications.

Sensitive Equipment, Power supplies for computers, medical devices and laboratory instruments.

Temperature Rise Consideration:

Designers may not always freely choose the switching frequency due to other component constraints.

As frequency increases, adjust flux density to limit core temperature rise.

Curves help select flux density while maintaining acceptable core loss levels2.

Remember that the right core material depends on the specific application, operating conditions, and desired performance. Engineers must carefully evaluate these factors to make informed decisions during transformer design

Designers may not always freely choose the switching frequency due to other component constraints.

As frequency increases, adjust flux density to limit core temperature rise.

Curves help select flux density while maintaining acceptable core loss levels2.

Remember that the right core material depends on the specific application, operating conditions, and desired performance. Engineers must carefully evaluate these factors to make informed decisions during transformer design

- High frequency transformer

- CMC DMC and filter inductors.

- Power Factor correction.

- High-frequency inductors

- low-frequency power line inductors

- specially designed inductors for decoupling and filter applications.

- Ferrite / Nanocrystalline / Powder Material

- Application onboard charger for electric Vehicels, line and noise filter exc.

Technisch Adviesbureau Soetens

Best

info @ tas.industries

Brainport Eindhoven

Best

info @ tas.industries

Brainport Eindhoven

Technisch Adviesbureau Soetens

Best

info @ tas.industries

Brainport Eindhoven

Best

info @ tas.industries

Brainport Eindhoven